| Author |

Topic Topic  |

|

mdtech12

United Kingdom

31 Posts |

Posted - 24/04/2017 : 22:24:38 Posted - 24/04/2017 : 22:24:38

|

Many thanks Dick...I can see where I was getting lost, I was using the "quick reply" instead of the "reply to topic". Pictures will now soon be displayed.

Mike |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 25/04/2017 : 06:34:02 Posted - 25/04/2017 : 06:34:02

|

Many thanks for that information Dick. I was using the quick reply button which does not have the links.

Anyway, here are some pictures to continue the story.

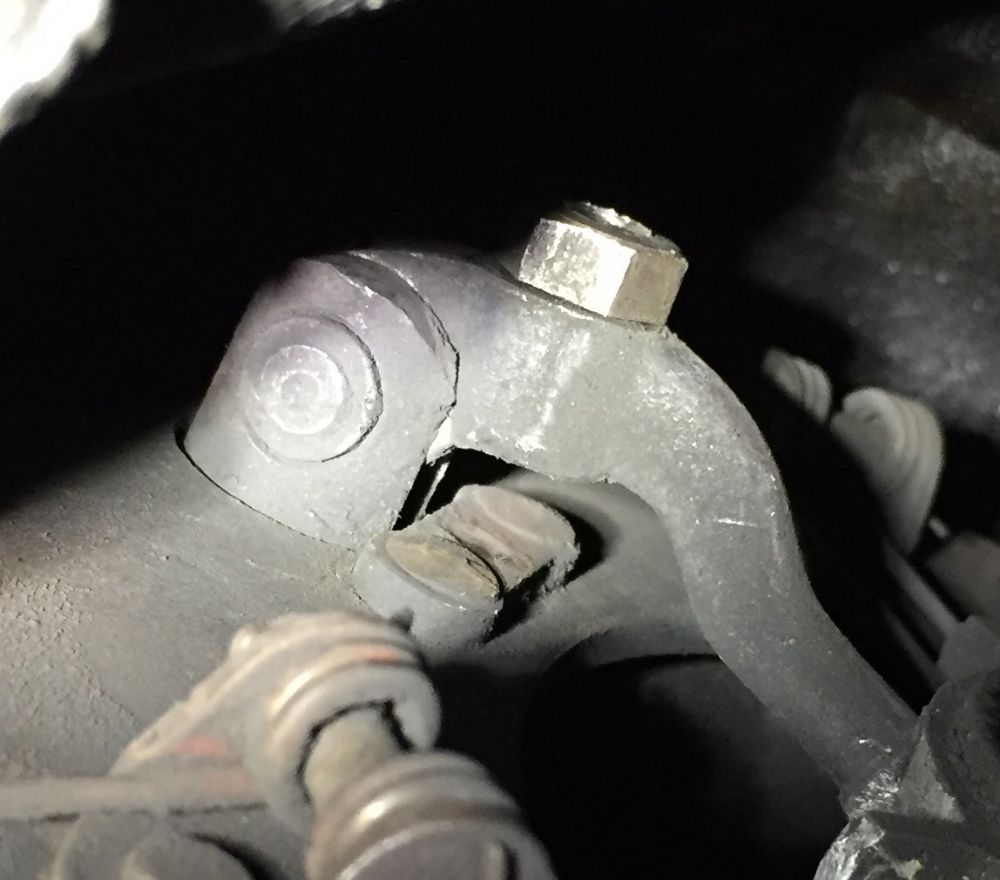

The missing lower part of the adjuster is obvious and the remaining set of parts show the scenario but does actually include one good adjuster:

Trying to source these apparently hardened items is proving tricky, so I have decided to buy some 1/4"tool steel, run a 1/4' BSF die down the bar, after turning the stud at one end, cutting a slot in the other and then case harden it using some hardening compound form either EKP supplies or Blackgates engineering in the UK. Meanwhile the car dismantling process is in full swing. I cannot thank people enough the for comments and help received so far in this thread.

Mike |

|

|

|

MaGic_GV

United Kingdom

868 Posts |

Posted - 25/04/2017 : 08:43:19 Posted - 25/04/2017 : 08:43:19

|

I have bought these from S&v in the past. Failing that I have some old ones somewhere, but new ones would be better!

Regards,

Graham

|

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 25/04/2017 : 10:06:54 Posted - 25/04/2017 : 10:06:54

|

Thanks Graham...I will contact S & V. Were they the socket head or slot head like the original?

Mike |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 25/04/2017 : 10:15:39 Posted - 25/04/2017 : 10:15:39

|

Graham, well at £1.85 each I've found its not worth the effort of switching my Myford on! I did check S&V's website but could not find them on there, then the guy on the phone said they only have approximately 20% of their its shown on the website so its best to phone and ask. I did ask if they have an automatic overnight clutch removal gizmo so when I woke up next morning it was there awaiting for me to work on it...alas they did not   Thanks for the heads up Graham, they are ordered. Thanks for the heads up Graham, they are ordered.

Mike |

|

|

|

MaGic_GV

United Kingdom

868 Posts |

Posted - 25/04/2017 : 10:23:15 Posted - 25/04/2017 : 10:23:15

|

They are allen key heads, be careful not to force them as they can break, I am told. You should be able to fit them through the aperture but don't drop anything!

Regards,

Graham

|

|

|

|

Colin Butchers

United Kingdom

1483 Posts |

Posted - 25/04/2017 : 10:36:15 Posted - 25/04/2017 : 10:36:15

|

I believe that the new adjusting screws which require an Allen key to adjust them only break if you over tighten the locking nut. So don't do it. Also bear in mind that a suitable chunk of sponge rubber poked into the inspection hole whilst turning the crankshaft slowly with the starting handle will cause the sponge to disappear down in to the depths only to reappear from the opposite side of the hole complete with any spare nuts, mouse droppings, fag-ends etc. which hitherto have been residing at the bottom of the hole.

Colin B. |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 26/04/2017 : 17:37:11 Posted - 26/04/2017 : 17:37:11

|

Ready to remove gearbox and bell housing but how is the bell housing support bar removed so I can undo the bolts and draw the assembly back...any ideas anyone?

Many thanks

Mike |

|

|

|

kimber

United Kingdom

1526 Posts |

Posted - 26/04/2017 : 18:04:26 Posted - 26/04/2017 : 18:04:26

|

quote:

Originally posted by Colin Butchers

I believe that the new adjusting screws which require an Allen key to adjust them only break if you over tighten the locking nut.

In certain circumstances the allen key replacement type will shear off very easily - I speak from bitter experience. I did explain why this happens on another thread some years back which a search might reveal. Will happily explain again if required

The originals are much harder to break and I have never heard of one breaking until now. l |

|

|

|

MaGic_GV

United Kingdom

868 Posts |

Posted - 26/04/2017 : 18:38:36 Posted - 26/04/2017 : 18:38:36

|

quote:

Originally posted by mdtech12

Ready to remove gearbox and bell housing but how is the bell housing support bar removed so I can undo the bolts and draw the assembly back...any ideas anyone?

Mike

I undid the bolts securing the end castings, so sliding the whole assembly back. But do you need to do this?

If you do, be sure to support the engine!

Regards,

Graham

|

|

|

|

Robin Macmillan

United Kingdom

415 Posts |

Posted - 26/04/2017 : 18:40:41 Posted - 26/04/2017 : 18:40:41

|

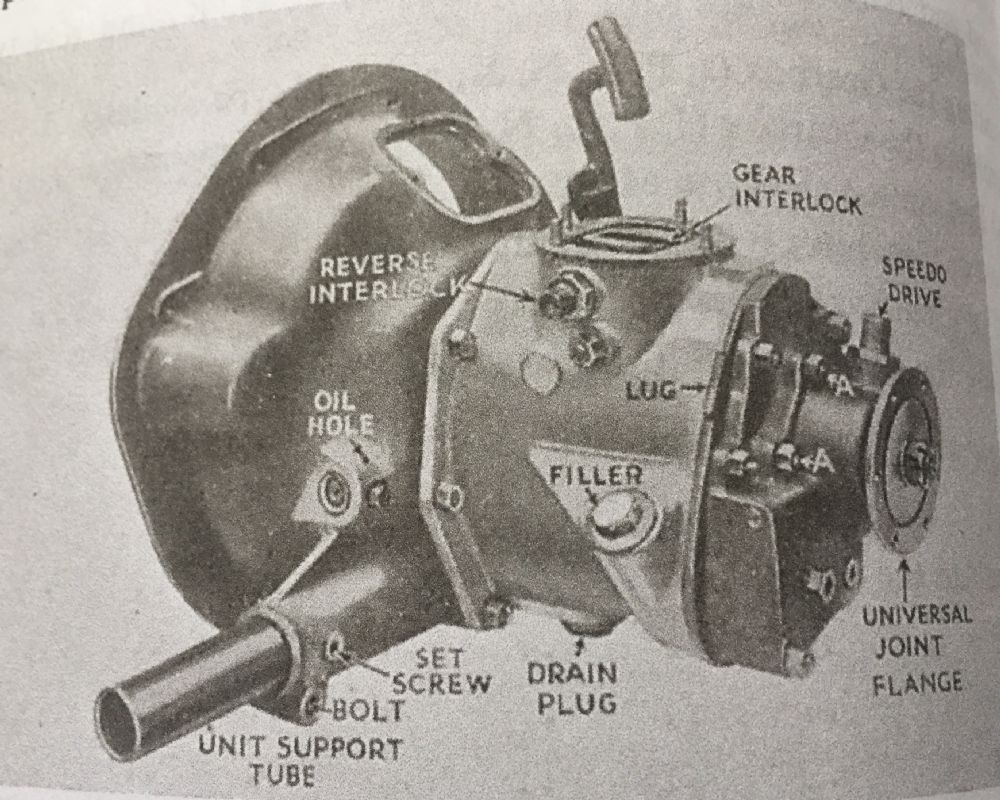

First support the rear end of the engine wooden blocks and a jack. It must be reasonably stable. Alternatively a rope and hoist arrangement can be used looping around the flywheel housing but obviously the bonnet needs to be removed. Make sure the car is chocked well so it cannot moe and upset the supports.. With either or both in place the bell housing bolts can be removed as they are no longer necessary to keep the rear of the engine in the position it is in. To the left and right of the "unit support tube" are the chassis mountings sittining inside the chassis section. 4 bolts on each side need to be removed On the mounting as as can be seen in the picture there is a clamp arrangement from the chassis mounting to the tube ... Loosen this. There may also be a locating dowel led screw , I cannot remember if on both sides but you can see it on the passenger side in the photo.

Jiggle things about until you can move the chassis mountings towards the middle of the vehicle. Leave them in the U-section initially as they support thins while you move the box towards the back of the car. Continue jiggling and pulling the gearbox to the rear and off it comes . I would advise removing the under tray if only to make access easier . Try not to have the gearbox hanging by the first motion shaft ! Jiggle the chassis mounts towards the centre of the car until they clear the U-section and then lift it out

An assistant is helpful though when younger I did it myself on a number of occasions

PB 0527 |

|

|

|

coracle

United Kingdom

1888 Posts |

Posted - 27/04/2017 : 00:14:44 Posted - 27/04/2017 : 00:14:44

|

It is fairly easy if you use a trolley jack under the gearbox to aid the jiggling without putting too much strain on the first motion shaft.

It is still possible to do single handed when older but takes longer and requires additional adjectives! |

|

|

|

Colin Butchers

United Kingdom

1483 Posts |

Posted - 27/04/2017 : 10:40:00 Posted - 27/04/2017 : 10:40:00

|

Robin. I withdrew my PA gearbox last month and had no great difficulty and I am 81 ! I have done it a few times before and I use a selection of wooden blocks which I place under the box to spread the load on the under-tray and it all slides out quite easily. Make sure that you move the castings which bolt the cross-tube to the chassis as far as you can get them in towards the gearbox and make sure that the brake cables and wiring loom do not get caught.

Colin B. |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 27/04/2017 : 13:26:27 Posted - 27/04/2017 : 13:26:27

|

Thanks for the information Colin. Im amazed at the number of fastener bits and pieces and rubbish I've found in the tray so far. No gold doubloons unfortunately!!

Mike |

|

|

|

kimber

United Kingdom

1526 Posts |

Posted - 27/04/2017 : 16:36:02 Posted - 27/04/2017 : 16:36:02

|

Mike asked off-line to explain my earlier posting in more detail.

Et voila:-

It depends on where the base of the Allen key recess sits when you have the correct clearance:-

The thickness of the recessed part of the adjuster is minimal (at the root of the thread) and if the base of the recessed portion sits well down inside the locknut it doesn't take much effort to wring it off when the tightening the nut (been there, done that). Whilst I agree with Colin they should not be over-tightened (incidentally, one of my pet hates on old cars, small fasteners being over- tightened) they do need to be reasonably tight as the last thing you want is one of the blighters coming undone. I am surprised that somebody has managed to do this on your car. I've never seen that before with the original components, which are normally pretty durable.

In my opinion, for the reason given above, the Allen key replacements are inferior to the originals. That said, I don't know if anyone has yet reproduced this part to the original spec' ?

I realise that many people use the Allen key type which should be fine but I would urge anyone doing so to check how far the hexagon recess extends inside the lock-nut when it is tightened.

I realise a diagram and some actual measurements would be really helpful but I'm quite busy just now.

Hope that helps.

|

|

|

Topic Topic  |

|