| Author |

Topic Topic  |

|

mdtech12

United Kingdom

31 Posts |

Posted - 23/04/2017 : 07:51:54 Posted - 23/04/2017 : 07:51:54

|

First post and a newbie to my PA so I hope someone can help. First of all it must be said that if I am in a gear and the clutch is depressed then the car does not move until the clutch pedal is released, proving hopefully that the engine is disengaged from the gearbox, BUT I have trouble getting into first with engine running without grinding away. Its feels as if the lay shaft is still spinning and this can be felt through the gear stick whilst trying to move into gear but whilst trying to ease into gear you can feel the internal gear train slowing down eventually allowing the gear to engage. Im sure the clutch is disengaging as above, so is this normal or is there something to look at. Can get into gear with ease when clutch depressed and engine not running.

M. R. Darby |

|

|

DSW

Germany

91 Posts |

Posted - 23/04/2017 : 08:56:09 Posted - 23/04/2017 : 08:56:09

|

Dear Mike,

Welcome to the joys of MMM motoring.

Gear changing should be a real pleasure when it is right.

Do you have issues when the car is already moving or at the very start from stationary?

If you start the engine and run at tick-over, depress the clutch and go into 1st gear it should engage within a tooth or two (it is a non-synchronized gearbox), but it should not grate for length of time. Only the oil in the gearbox will slow it, so when hot or cold will be somewhat different.

If serious gear tooth grating happens then something must be dragging - I would guess clutch plate too thick (there were 2 designs) or spigot in flywheel.

Has anything been rebuilt recently?

Obviously check the correct clearances of the pedal release bearing found under the Aluminium "MG" plate on the bell housing - you can also see some of what is happening by looking in there. There are forum posts on this (use Search).

If you are already driving/moving and have this issue, then you must double declutch - ie synchronize the gear speeds yourself - when changing down, and usually wait a short tad going up.

Let us know when your issue occurs

David |

|

|

|

George Eagle

United Kingdom

3228 Posts |

Posted - 23/04/2017 : 10:28:21 Posted - 23/04/2017 : 10:28:21

|

Hello Mike

Welcome to our Triple-M we site and congratulations on buying your PA.

From the symptoms you describe I think the cause must be the clutch not fully disengaging? As David has noted there are two types of clutch design and maybe that your clutch is assembled with a mixture of parts.

I know this topic has come up for discussion before - a search of archived topics should find the necessary info.

George

L2023 |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 23/04/2017 : 14:17:37 Posted - 23/04/2017 : 14:17:37

|

Many thanks for the prompt replies guys...much appreciated. David, no problems when in motion going from 2-4-4 just when stationary and yes it is worse when hot, no doubt due to the oil been warmer and hence lower viscosity. I have also checked there is oil in the box too...140 grade i believe.

I have no record as to when the clutch was last looked at, but I must admit, I too have wondered if the clutch is releasing fully. I note there are three fingers which all need to be adjusted...is tis straightforward as the original text in the hand book looks a bit daunting?

M. R. Darby |

|

|

|

PeterL

United Kingdom

1711 Posts |

Posted - 23/04/2017 : 14:45:25 Posted - 23/04/2017 : 14:45:25

|

Looking in through the hatch will reveal lots... Barry Foster's article on clutch adjustment, Clutching at Straws is a must for first timers (and for me still!!!

now where is that? One of the Year Books I think... someone will know... |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 23/04/2017 : 16:15:08 Posted - 23/04/2017 : 16:15:08

|

Thanks Peter..its "Clutch – clutching straws B Foster 2006 page 69" but can't yet find the 2006 year book...anyone else know where it is please.

M. R. Darby |

|

|

|

mgmog

United Kingdom

462 Posts |

|

|

mdtech12

United Kingdom

31 Posts |

|

|

Simon Johnston

United Kingdom

5999 Posts |

Posted - 23/04/2017 : 18:20:55 Posted - 23/04/2017 : 18:20:55

|

Barry Foster's article is indeed excellent - buts it's for the clutch found in the M, D, J and F engine, not the P Type.

Simon J

J3437 |

|

|

|

correlejco

United Kingdom

251 Posts |

Posted - 23/04/2017 : 19:47:09 Posted - 23/04/2017 : 19:47:09

|

Just a thought - possibly you don't have a problem. You say that the spinning gearbox shafts slow down 'eventually'. Mine takes up to 3 or 4 seconds to stop when the oil is warm - this seems like a long time when the lights go green! I don't think I've got any clutch drag - just a free-spinning gearbox.

We're all used to synchro on 1st gear these days and instant crunch-free engagement. I recall on my MGAs that to engage 1st quickly one had to snick the lever into 2nd to stop the 1st motion shaft. Not an option for MMMs though. But I endorse the recommendation that you check the clutch adjustment - and make sure your idle speed isn't too high.

John - 1934 NA0492 |

|

|

|

LewPalmer

USA

3209 Posts |

Posted - 23/04/2017 : 23:12:14 Posted - 23/04/2017 : 23:12:14

|

Don't forget that there is a clutch pedal adjustment via a bolt on the bell housing. I had a lot of trouble getting into first gear on my PB until I readjusted the pedal stop. There was simply not enough free throw to fully disengage the clutch. A simple adjustment put things right.

Lew Palmer

PA1169, PB0560 |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 24/04/2017 : 07:36:14 Posted - 24/04/2017 : 07:36:14

|

Hi Guys. Simon, yes you are correct I discovered the article by Barry Foster was not applicable to my PA which has 4 operating levers and separate clutch operating disk springs. Anyway, more information now after removal the inspection plate. It was soon apparent that the clutch operating disk (onto which the operating levers press) was sitting at an angle, with the gap between it and the release bearing varying from approx 1/8" to 3/16" (the required gap I believe on the PA) around its circumference. A quick crank of the engine confirmed the mechanism was way out of adjustment and the operating disk was indeed not running true. Looking at the clutch withdrawal set screws (slotted and not hex on mine) I proceeded to get setup to do some adjusting after tying up all my adjustment gismos with string! Spinning the the engine over to each of the 4 levers using the starting handle, I discovered with horror that one lever was loose about its pivot point allowing me to rock it back and forward with ease. It seems at the moment that its is not connected to its clutch drawing bolt...not having seen the mechanism on the bench I can't yet visualize the levers construction as it passes through the clutch cover, I will continue to check later today but am beginning to reside to the fact I may have to remove the clutch to work on. LEW, I did look at the clutch pedal adjustment but I must admit the pedal on full depression at the moment goes no where near the adjustment bolt on the bell housing...I think its supposed to be 1 1/2".

Thanks for all your comments, please feel free to continue, if only for moral support..lol.

.

Mike Darby |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 24/04/2017 : 18:01:42 Posted - 24/04/2017 : 18:01:42

|

I found that the lower portion of thread on the adjuster of the arm had broken off (guess where that is lying) so tried to see what the other adjusters were like. Two of them the adjuster simply broke away leaving the lower part in place. Looks like a clutch out procedure...cant find a thread on this so if anyone can give me a quick list that would be great.

Mike Darby |

|

|

|

kimber

United Kingdom

1526 Posts |

Posted - 24/04/2017 : 18:56:43 Posted - 24/04/2017 : 18:56:43

|

| As a matter of interest were these the original type with a screwdriver slot or replcements with a female hexagon? (I'm guessing the latter...) |

|

|

|

mdtech12

United Kingdom

31 Posts |

Posted - 24/04/2017 : 19:44:39 Posted - 24/04/2017 : 19:44:39

|

The slotted type and from the condition of the slots have seen a lot of wrong sized screwdrivers...any idea how to attach photos?

Mike Darby |

|

|

|

DickMorbey

United Kingdom

3672 Posts |

Posted - 24/04/2017 : 21:08:28 Posted - 24/04/2017 : 21:08:28

|

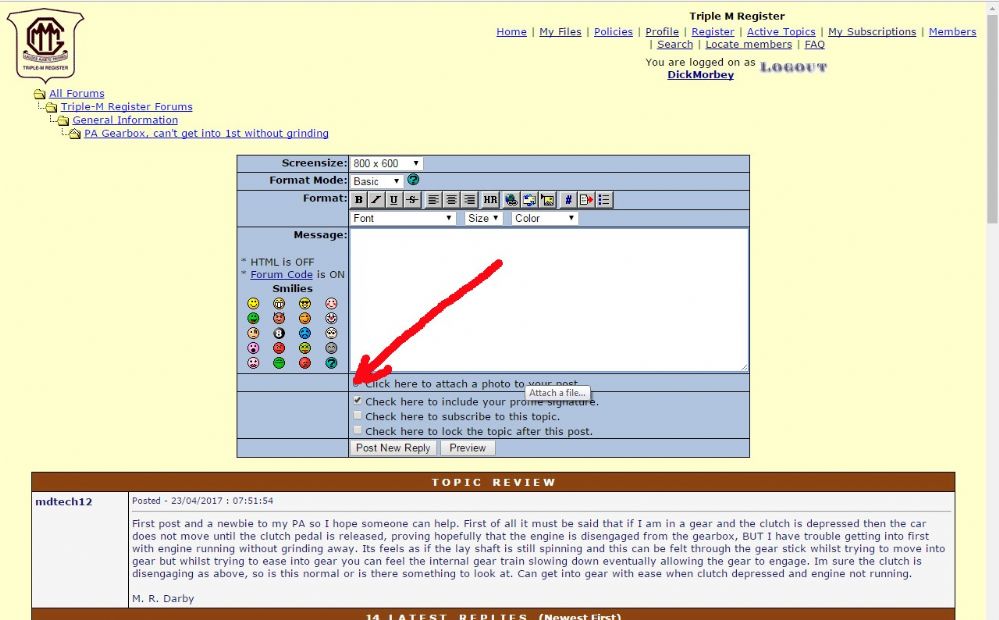

Attaching photos:

Select 'Reply to topic' and click the paperclip on this screen:

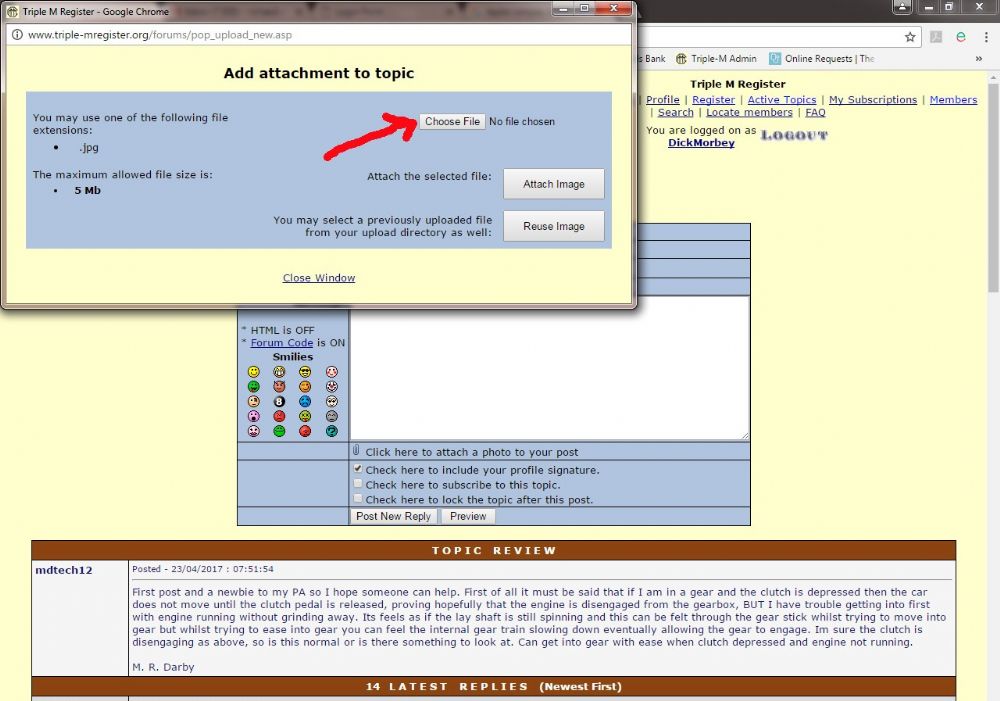

Then click the choose file button:

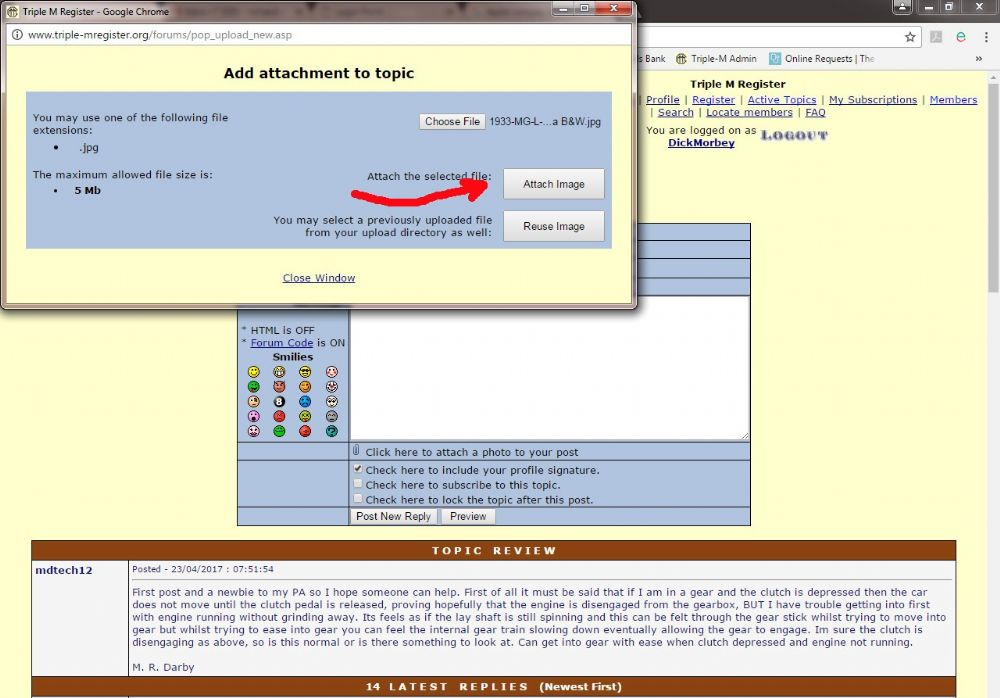

When you have selected the image file you want to attach then click this button:

Hey presto!

Dick Morbey

PA/PB 0743

Frieth, Oxon, UK |

Edited by - DickMorbey on 24/04/2017 21:10:08 |

|

|

Topic Topic  |

|